how does vapor honing work

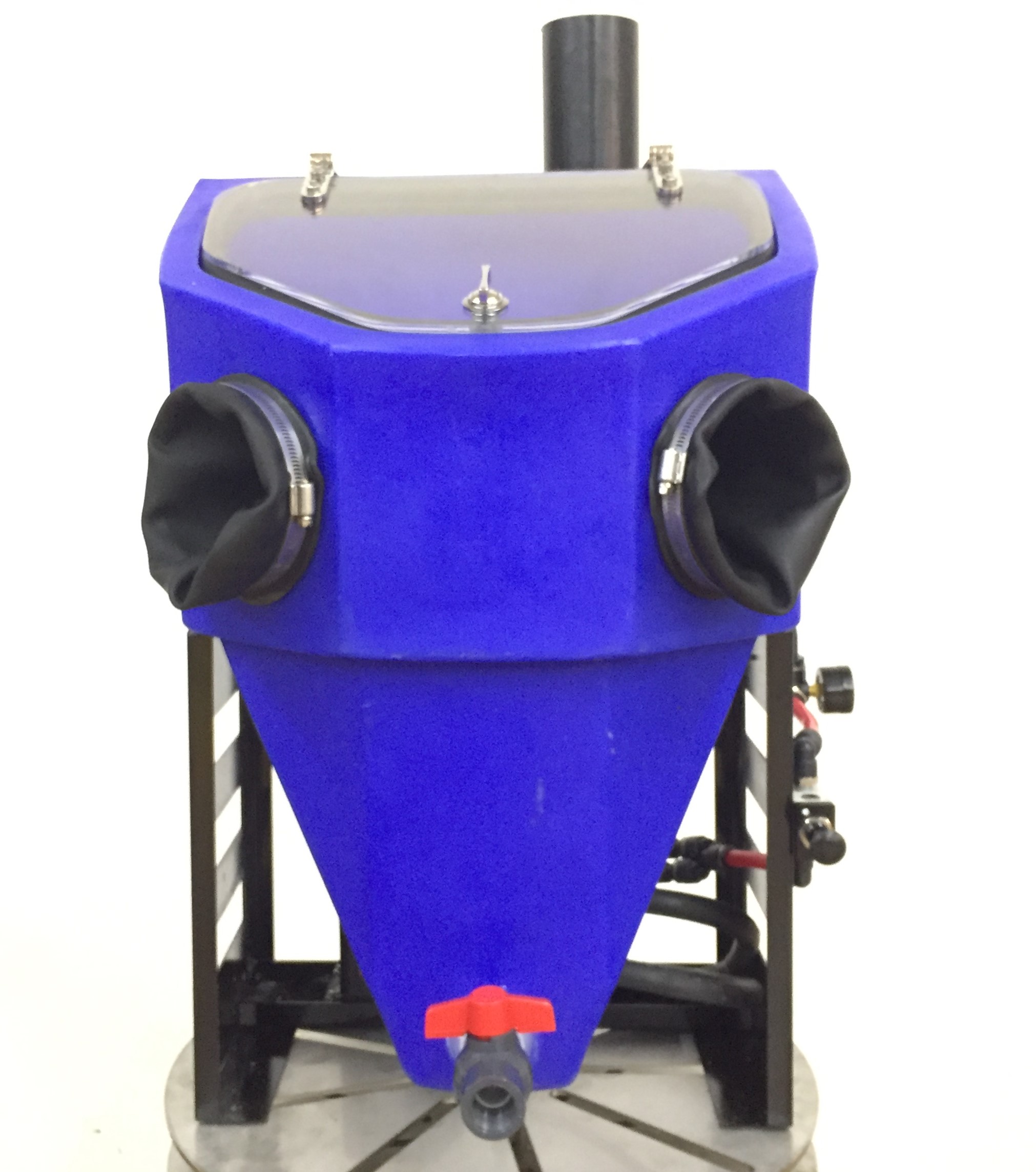

If we need to clean your parts or remove gaskets bearings or seals additional charges may apply. Combining water and abrasive together forms a slurry which is propelled at the part surface using compressed air.

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

The process has numerous functions for example-.

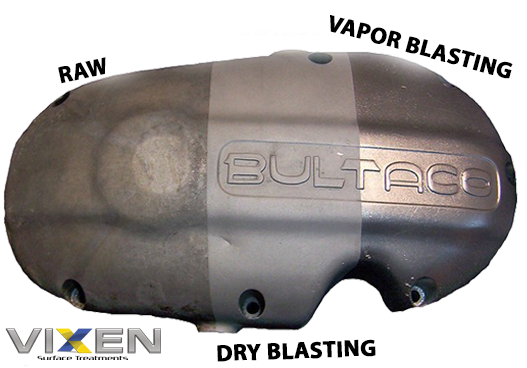

. Vapor blasting also known as wet blasting liquid honing or dustless blasting is a process that uses pressurized water and abrasive material to remove contaminants corrosion residue or coatings from a surface. Commonly called vapor blasting or wet blasting. Abrasive selection is made based on desired surface roughness or aesthetically desired finish.

Wet blasting can also be known as vapor blasting slurry blasting and liquid honing. Fine abrasives between 2 and 400 micron are suspended in water and forced at the material at high velocity to remove impurities such as heat treat scale. It is the ideal for all types of materials metallic and non-metallic.

Client provides the parts and completed parts are returned in 30-45 days. It leaves a smooth satin finish and is much more gentle to the surface than dry sand or glass bead blasting. Vixens Aquablast range of wet blasting machines uses the vapor blasting process to simultaneously degrease and blast industrial components of many different shapes and sizes.

Tuttle Motorsports auto restoration auto. The Liquid Vapor Honing process is applied to metals for the following reasons. Services are billed by the hour 60 per hour and the time it takes to complete a project depends on the condition and cleanliness of the parts you furnish.

Blast Wash Systems has partnered with Vapor Honing Technologies Force Automation to deliver the next great thing in advanced robotic wet blasting. The second is a pumped slurry with air added to create a more aggressive hone action. Using a fine glass bead slurry mix with 25-60 psi 37 cfm this is a high volume low pressure process that gets down into the fine areas removing any dirt grime rust or corrosion without removing any metal.

Vapor Honing is the same process as wet blasting and vapour blasting. Tuttle Motorsports custom automotive design and fabrication automotive restoration and performance upgrades. Water abrasive and compressed air are 3 ke.

Vapor honing uses water as a lubricant. Vapor honing is a wet blasting process which uses very fine glass beads and water under air pressure. There are numerous reasons why wet blasting is becoming more favorable over dry blasting and this is primarily because of its two key features.

How Does Vapor Honing Work. Sure it will work with a smaller compressor however it WILL just take LONGER and you will be waiting for the compressor to catch up. It is commonly used for cleaning aerospace parts and.

Firstly the finish is achieved by the flow of water borne abrasive not by impact and secondly because it is a dust-free process. A very tiny abrasive can be added. Before you start the cleaning process you need to pick the type of abrasive youll use to clean your part.

What is vapor honing. HOW MUCH DOES VAPOR HONING COST. Vapor honed has two common meanings.

Vapor honing also referred to as vapor blasting or wet blasting is a surface refinishing process used to clean and restore surfaces. The more proper one is an aspirated water as in a common blast cabinet except it is water instead of grit. Once you concoct your slurry it goes into the sump at the.

Vapor blasting also known as wet blasting or liquid honing is rapidly becoming the number one choice for applications requiring the highest quality of surface finish. No matter the size or weight of a part we can customize a system to meet your needs whether it be a single or multi part process. Vapor Honing Technologies Lilhonda Com Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa Vapor Honing Jim S Workshop Vapor Blasting.

What is Vapor Honing. The abrasive nature of the cleaning means the part is scrubbed clean by default. Instead of dry abrasive media used in sandblasting it uses a combination of water compressed air detergents with finer and gentler media to remove oxidized metal and corrosion.

This will also add a small amount of tiny abrasive. Wet Blasting Equipment Vapor Blasting Services. Perfect for use on new components or refurbishment of any type of machinery.

The vapor blasting process provides the highest quality soft surface finish. Its perfect for restoration work because it makes the metal surface look like new but does not remove metal like sandblasting. All orders are subject to a 1 hour minimum charge.

Vapor Honing or wet blasting is a process utilized for precision surface finishing. Vapor Hone services- We do this work hourly. Makes your old parts look like new.

Restore parts to OEM finish or prep for powder coating and painting with our vapor honing service. Vapor honing is also an excellent option to remove very fine burrs tool marks or for applications where. How does vapor honing work Tuesday March 1 2022 Edit.

Vapor Blasting What It Is Costs And Shipping

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

Vapor Honing Services What Is Vapor Honing And Does It Work

Vapor Honing Blasting Superfly Garage

The Tool You Need For Surface Finishing Vapor Honing Technologies Youtube

Vapor Honing Technologies Lilhonda Com

A Simple Introduction To Vapor Honing Issuu

Vapor Hone 1000 Wet Blasting Equipment Blast Wash Systems

Vapor Blasting Services Wet Blasting Vapor Honing Technologies

What Exactly Is Vapor Honing 5 Things You Should Know

Slurry Pumping System S Vapor Honing Technologies Youtube

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Vapor Honing An Engine The Ultimate Guide

Slurry Blasting Vapor Blasting Equipment For Sale Vapor Honing Technologies

Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube